Order Packing

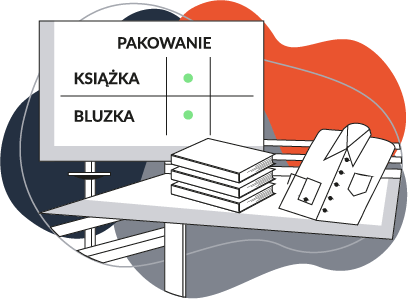

Verification of the correctness of the goods being packed for the order

Just before the products are put into the box, Way2Send checks again that the goods being put in are definitely the ones selected by the customer. If everything is correct, the system will allow the parcel to be packed. If not, it will show what the discrepancy is and, until the correct goods are scanned, it will not close the order. This means an end to the problem of incorrectly completed orders.

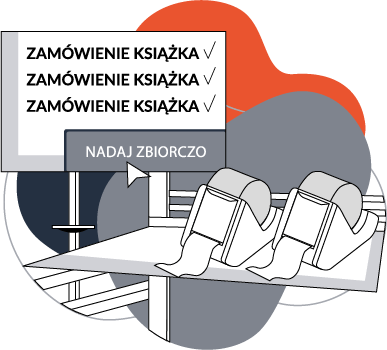

Possibility of bulk shipping

Collective shipment will speed up your work especially when introducing new goods, pre-orders or multiple orders with one and the same product. With the goods already packed, Way2Send will print labels for each order, starting with the oldest. The packer does not even need to know which order they are currently handling. Each subsequent order will be the same, with the only difference being the data on the courier label. Each subsequent order will be the same, with the only difference being the data on the courier label.

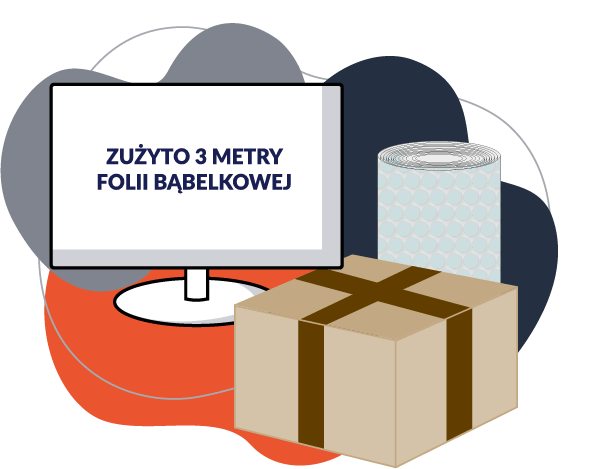

Scanning additional services, e.g. filler

The costs a company incurs when packaging online orders are not only the work of the warehouse or the customer service office, but also the costs of the products needed for packaging, such as adhesive tapes, cartons of different types and sizes, fillers and tissue paper or leaflets. Knowing how much of these things are consumed allows you to monitor costs and also observe whether anything needs to be optimised. In the case of fulfilment, such information allows you to bill the customer for all components of the outsourced service, and you have all costs in the shop under constant control.

Shelving of incomplete orders

When unsuitable goods are collected or not found in the warehouse (e.g. because they are missing or damaged), it may be necessary to relocate the product for further clarification. In such a situation, once relocated, the system remembers where such an order is located on the 'to be clarified' rack. When the issue is clarified and the missing goods are brought in, the system will indicate the specific place on the clarification rack where this order is located. In addition, the system has the option of suggesting which orders could potentially contain missing goods. Based on these suggestions, the sorter makes possible relocation decisions.